AllOnScale delivers its first 100% 3D-printed scale model

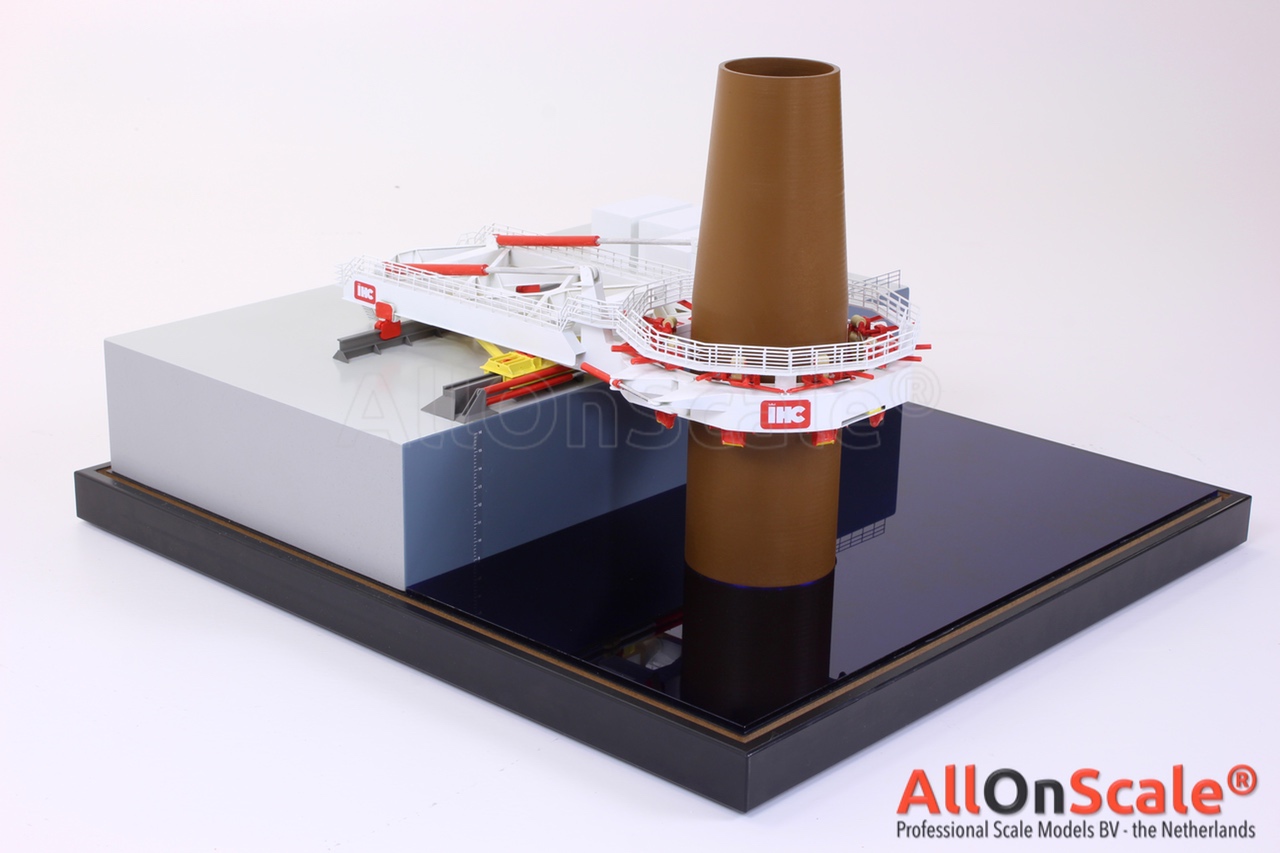

The award-winning Hi-Traq power cable trencher from Royal IHC is a unique self-leveling suspension system for the installation and burial of offshore power cables. The highly innovative and versatile four-track tooling platform provides unequaled steering and traction performance which facilitates trenching operations in the challenging sub sea environments found at offshore renewables locations.

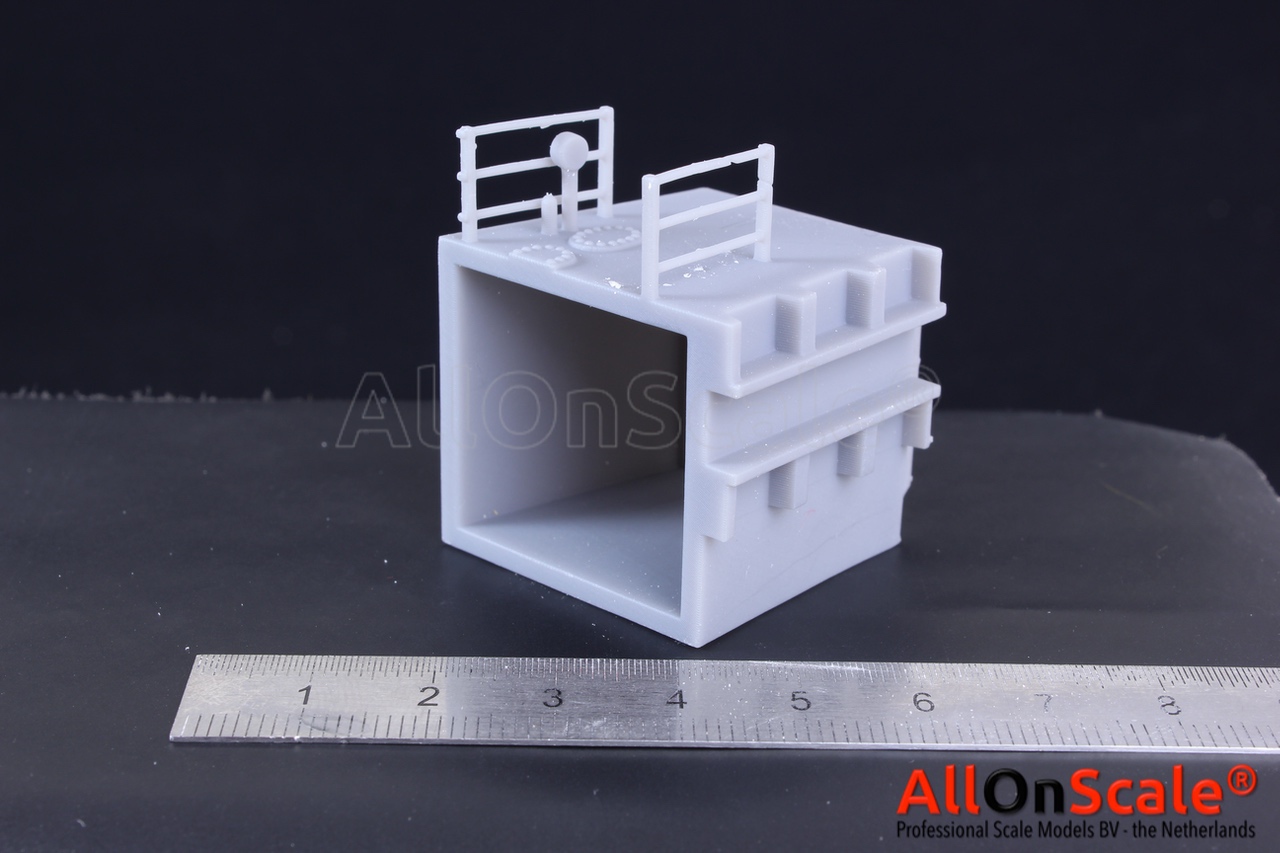

In May 2017 Royal IHC approached AllOnScale to create a scale model of the Hi-traq to be used at fairs and customer visits. Due to the high complexity of the model it would be extremely difficult and time consuming to produce this manually, however since this year AllOnScale has added an impressive capability to its range. The large volume 3D-printer from market leading 3D-systems delivers models that rival hand built models.

AllOnScale received the CAD model of the Hi-traq and started to break it up into printable and to be painted parts. The separate files where made printable, some by hand, some using specialized software. All CAD work, printing, and finishing were done in house in the Netherlands.

After printing, the parts where placed in an oven to remove the support wax used while printing and then washed. The quality of the printed parts is so high that sanding is not necessary and paint can be applied immediately. As the parts originate from a CAD file the assembly is easy and all fits together snugly. All our models are delivered with a baseplate, nameplate and acrylic cover. In this case we simulated the ocean floor with some real sand.

This model was created in 4 weeks and contains each and every detail from the CAD file right down to the nuts and bolts. If handcrafted this would take 10-15 weeks to complete. AllOnScale’s ability to deliver fully handcrafted, fully printed or combination of the two gives us unlimited potential.

More info @ allonscale.com

Contact us @ sales@allonscale.com

More info about Hi-traq visit: https://www.royalihc.com/en/products/offshore/subsea-equipment/hitraq