FDM is short for Fused Deposition Modeling and is the most common technology for simple and fast prototyping. The material is delivered as rolls of wires and is fed to the moving head of the 3D-printer. Inside the head the plastic is locally molten and deposited through a fine hot nozzle onto the build plate. The head is computer controlled to follow a certain path in x and y direction. As soon as the material is deposited it cools and becomes hard again. When the nozzel has traced the full area of that layer, the build area drops by 0.1mm and the proces is repeated.

SLA is short for Stereolithography Apparatus and is the oldest form of 3D printing. The material is a liquid and is delivered in bottles. The build area consists of a small bath with a see-through bottom. The bath is filled automatically or manually by the material. After this the build platform drops down into the bath leaving a 0.1mm gap between the build platform and the bath bottom. A laser or other UV source traces the layer from below through the see-through bath floor. When the full layer has been traced the build platform moves up 0.1mm and the process is repeated.

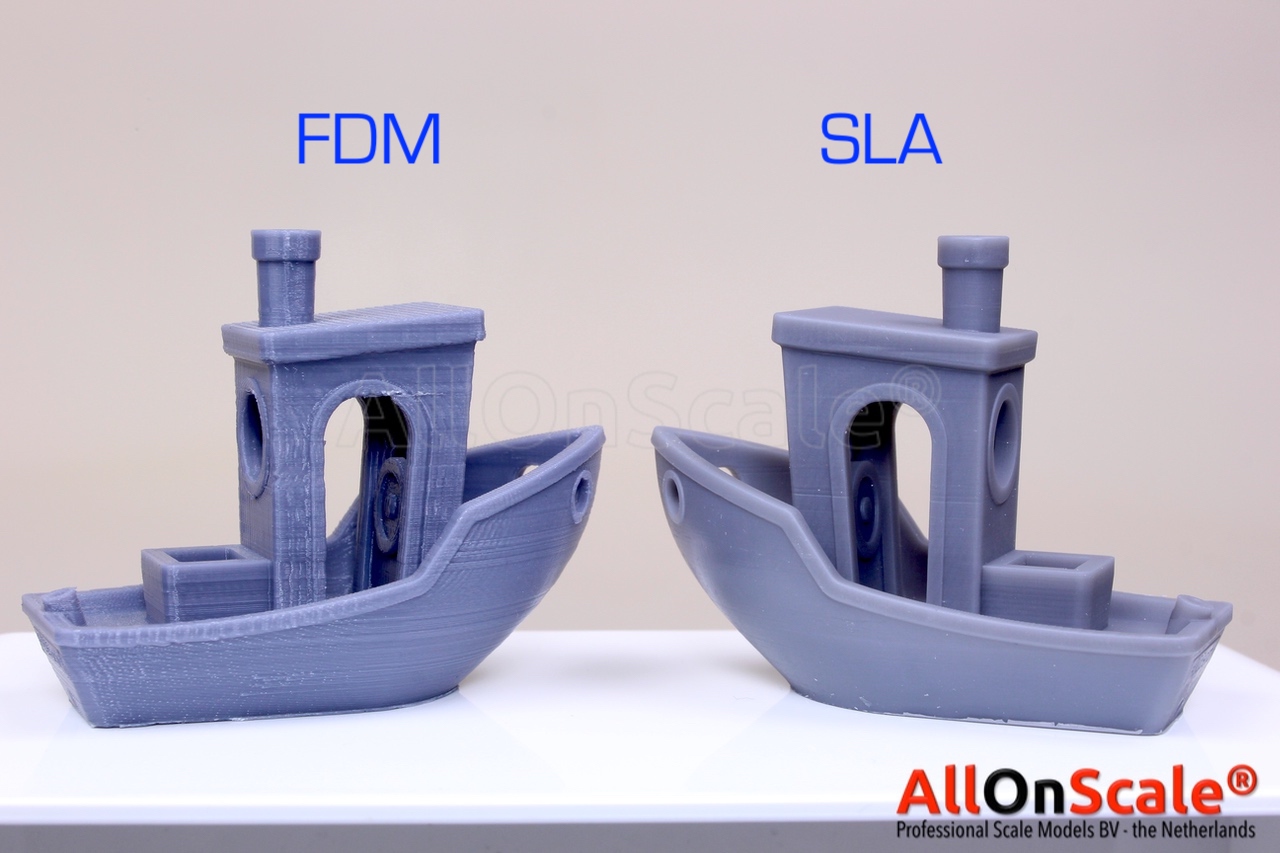

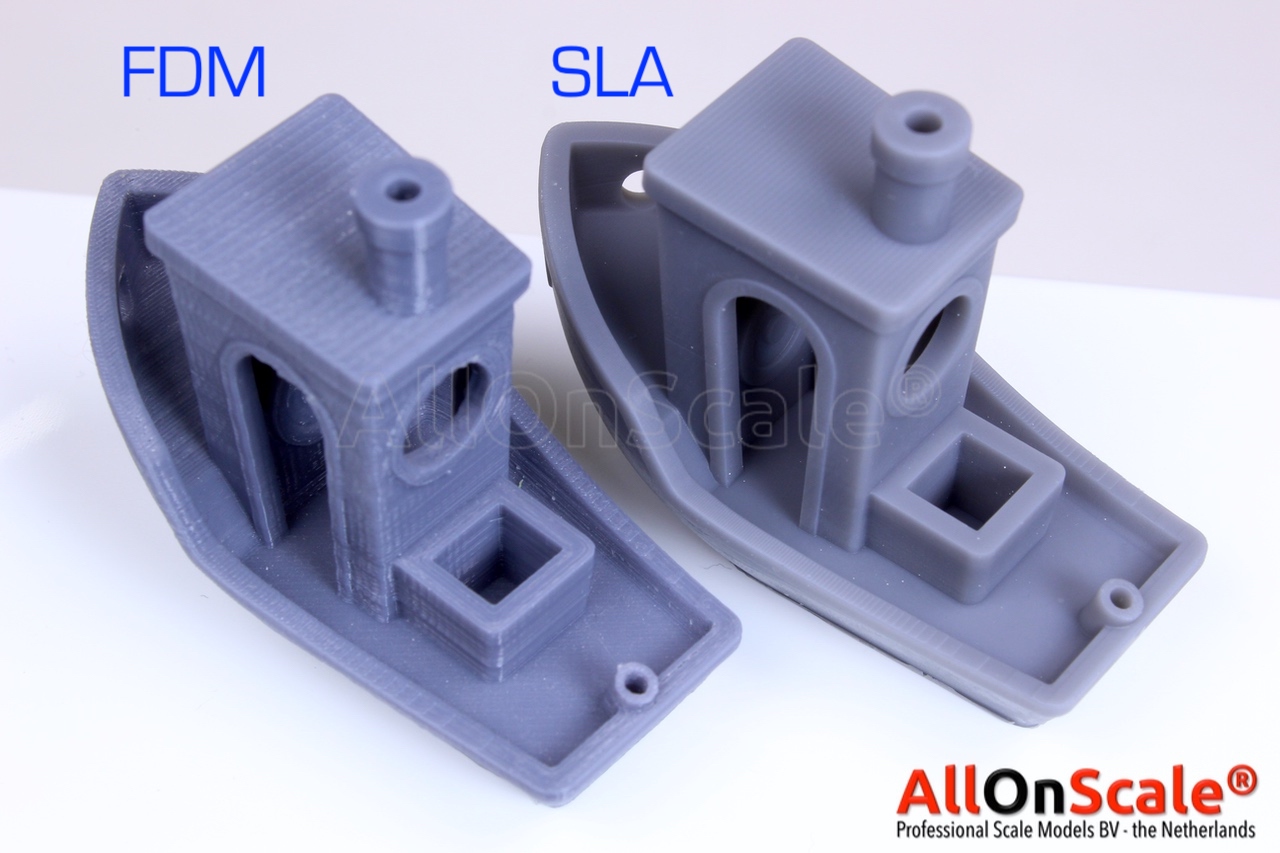

The Advantages from SLA are clear. Prints come out much smoother and the visible layer lines are at a very minimum. Most parts can immediately be used and painted without much sanding. Small details like the text on the back are more profound and clear. The laser size is 0.085mm compared to the 0.4mm nozzle size of a FDM printer making it able to recreate very small details. The parts of SLA rival much more expensive industrial solutions.

The Similarities between FDM and SLA are that in both systems layers can not be printed in thin air. If your part has an overhang it will need to be supported in either system for the model to be correctly built. So both technologies use support structure to support the model and overhangs during the print. These supports will need to be removed after printing.

The Disadvantages from SLA are that it is more expensive than FDM (Although still much cheaper than industrial solutions). In FDM only material is driving the costs and the occasional nozzle replacement. In SLA the material is about twice as expensive and the build tray is a part that will need replacement after a number of prints. The prints from SLA will also need to be cleaned after printing which uses up time and cleaning resolution.

The short summary is:

- SLA is superior in delivering smooth parts.

- SLA gives great detail level

- Keep in mind that SLA is up to twice as expensive as FDM.